2026 Best Pre Engineered Buildings for Cost Efficiency and Versatility?

The growing demand for cost efficiency and versatility in construction has made pre engineered buildings (PEBs) a popular choice. According to a report by Grand View Research, the global market for pre engineered buildings is expected to reach USD 39.88 billion by 2026. This rapid growth indicates a shift towards more sustainable and adaptable building options.

Renowned expert in modular construction, Dr. Emily Caldwell, emphasizes, "Pre engineered buildings offer a unique blend of flexibility and affordability." This statement resonates with many businesses seeking to optimize their resources while ensuring high-quality standards. PEBs are designed for quick assembly, reducing labor costs significantly. However, it is crucial to consider potential quality concerns. While PEBs are often seen as a solution, not all manufacturers meet stringent quality criteria.

Challenges such as limited customization options can also arise. These factors prompt industry stakeholders to critically assess their choices. The balance between cost savings and structural integrity remains a key discussion point. As the industry evolves, embracing innovation in pre engineered buildings is essential for meeting future demands.

2026 Trends in Pre-Engineered Building Design and Construction

The pre-engineered building (PEB) market is evolving rapidly. In 2026, design trends lean towards sustainability and adaptability. Studies show that PEBs can reduce construction time by up to 50%. They offer flexibility in layout, which attracts various industries.

Modular designs are gaining popularity. They allow for easy relocation and expansion. A recent industry report highlights that 70% of companies favor PEBs for their quick assembly and cost efficiency. However, not all designs account for long-term durability. This can lead to higher maintenance costs down the road.

Innovative materials are essential for future PEBs. Green building materials, like recycled steel, are becoming mainstream. Yet, the challenge remains in finding a balance between cost and quality. As the industry pushes forward, stakeholders must reflect on their choices. The landscape is shifting, and adaptability will be key.

Cost Analysis: Comparing Pre-Engineered Buildings to Traditional Structures

When considering cost efficiency, pre-engineered buildings often shine compared to traditional structures. These buildings typically require fewer raw materials and less labor, which translates to lower overall expenses. Additionally, their construction time is significantly reduced, leading to quicker occupancy and an earlier return on investment. This rapid build can be a game-changer for many businesses that prioritize speed.

However, embracing pre-engineered solutions does come with challenges. One concern is the perception of reduced customization. While these structures are versatile, they may not meet very specific architectural needs. It's important to reflect on whether flexibility is a priority for your project. Also, planning regulations and local building codes can complicate matters, potentially driving up costs unexpectedly.

Exploring long-term benefits is crucial. Energy efficiency is a factor where pre-engineered buildings excel. The right materials can lead to significant savings on energy bills. Yet, initial cost analysis may overlook these advantages. Building owners should weigh short-term savings against long-term investments carefully. The decision process requires thorough analysis, ensuring all factors are considered.

Key Features of Versatile Pre-Engineered Buildings for Various Industries

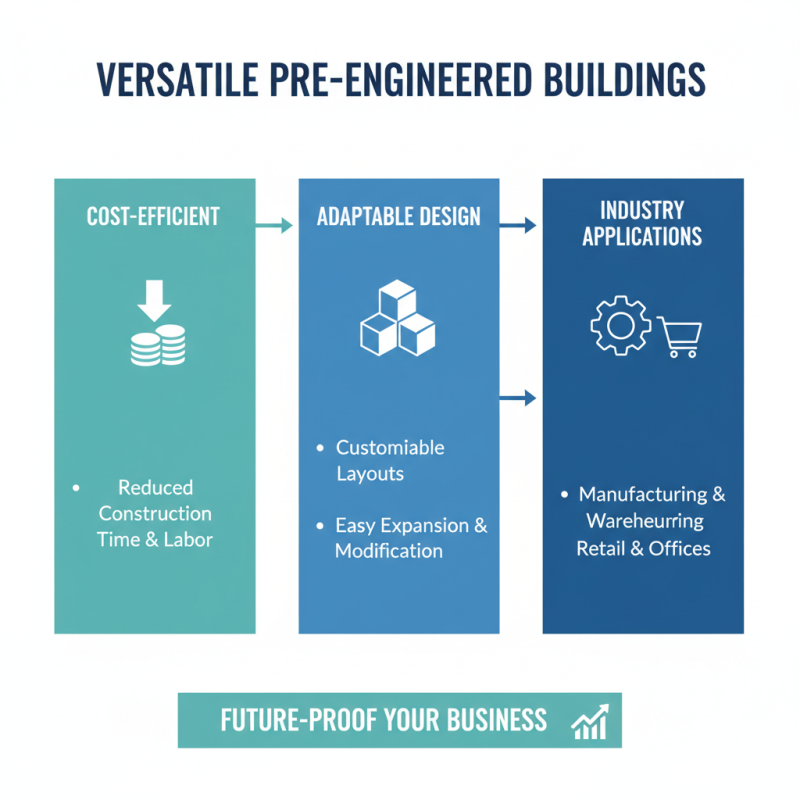

Versatile pre-engineered buildings offer a blend of cost efficiency and adaptability. They cater to various industries, from manufacturing to retail. One of the key features is their customizable design, allowing for expansion and changes. Business needs can evolve, and these buildings can adjust without major renovations. This flexibility is invaluable for startups or dynamic companies.

Another notable feature is the quick assembly process. Traditional construction can take months, but pre-engineered models reduce time considerably. This speed means businesses can start operations sooner. However, some might find limitations in design options. This could pose a challenge for highly specialized industries. Addressing these shortcomings requires careful planning and foresight.

Energy efficiency is a prominent consideration. Pre-engineered buildings often come with advanced insulation and sustainable materials. These elements reduce long-term operating costs. However, it's essential to evaluate if the upfront investment aligns with future savings. Balancing initial costs and operational efficiency may require deeper inspection.

Impact of Pre-Engineered Buildings on Sustainable Construction Practices

Pre-engineered buildings (PEBs) are transforming the construction landscape. These structures use factory-made components. They typically require less energy to produce. This can lead to a smaller carbon footprint. However, the impact is not always straightforward. The efficiency gains may be offset by transportation emissions from factory to site.

Sustainable practices in construction focus on reducing waste. PEBs can minimize material usage due to their design flexibility. They allow for quick assembly on-site. This can shorten project timelines. However, the reliance on standardized parts can limit creativity. Not all designs may fit neatly into pre-engineered systems. Builders might face challenges in meeting unique client needs.

Additionally, the longevity of materials must be evaluated. PEBs often use steel and other durable materials. While these materials resist weather elements, they may require substantial energy to produce. It's essential to consider the life cycle of these buildings. Are they truly sustainable? Continuous reflection on these issues is vital for promoting better practices in modern construction.

Future Innovations in Pre-Engineered Building Materials and Technologies

The future of pre-engineered buildings looks promising with advancements in materials and technologies. Innovations like eco-friendly options are emerging. Sustainable materials, such as bamboo and recycled steel, offer both strength and lower environmental impact. These choices can reduce a building's carbon footprint significantly.

Technology is changing how these structures are designed and constructed. 3D printing is a notable example. It allows for rapid prototyping and customization. This can lead to cost savings, but may raise questions about quality control. Does speed compromise durability? Engineers must address these concerns as designs evolve.

Smart building technology is another exciting area. Integrating IoT can optimize energy use. Smart sensors monitor conditions, adjusting heating and cooling as needed. A building may become more efficient, yet reliance on tech can also introduce vulnerabilities. What happens if systems fail? Addressing both opportunities and challenges is crucial in shaping the future of pre-engineered buildings.

Related Posts

-

Innovations in Building Technology Shaping the Future of Sustainable Architecture

-

Exploring the Advantages of Pre-Engineered Steel Buildings for Your Next Construction Project

-

Top 10 Benefits of Steel Structure Buildings for Your Construction Projects

-

Innovative Steel Framing Solutions for Sustainable Construction Projects

-

10 Best Advantages of Using Steel Structure Buildings for Modern Construction

-

Why Choosing Eco Friendly Building Materials Benefits the Environment and Your Home