2026 How to Design and Build a Steel Structure Efficiently?

In the evolving landscape of construction, efficient design and construction of steel structures is paramount. Renowned expert Dr. Emily Carter has emphasized this by stating, "A well-designed steel structure can stand the test of time, both in endurance and efficiency." Designing a steel structure is not merely about aesthetics or cost; it also involves a keen understanding of materials and structural integrity.

Engaging with professionals in the steel structure industry reveals the importance of precision. Many projects face challenges like unexpected weight loads and environmental factors. These issues can lead to costly setbacks. However, with advanced technologies and methods, such as BIM (Building Information Modeling), these concerns can be addressed proactively.

Reflecting on past projects often sheds light on common pitfalls. Design miscalculations and poor communication can compromise a structure’s efficiency. A successful steel structure requires collaboration among architects, engineers, and builders. This unity streamlines processes and minimizes errors, ultimately leading to a sustainable and resilient end product. The journey to a well-built steel structure welcomes adaptations, but the ultimate goal remains: efficiency and durability.

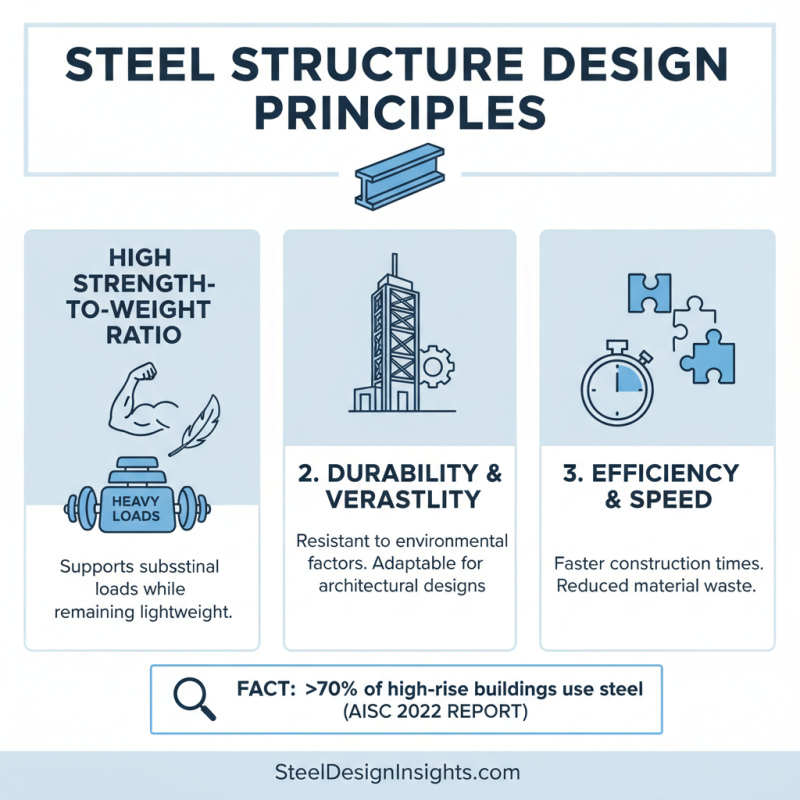

Understanding the Basics of Steel Structure Design Principles

Understanding the principles of steel structure design is essential for achieving efficiency. Steel structures offer high strength-to-weight ratios. This means they can support heavy loads while being relatively light. According to a 2022 report by the American Institute of Steel Construction, over 70% of high-rise buildings utilize steel due to its durability and versatility.

When designing steel structures, consideration of load factors is vital. Designers must analyze live loads, wind loads, and seismic forces. A miscalculation could lead to structural failures. For instance, studies show that approximately 5-10% of steel structures face issues related to inadequate load assessment. This highlights the need for meticulous calculations and reviews.

Construction timelines can often be compressed, leading to rushed designs. A survey indicated that 40% of projects experience delays from design changes made late in the process. These alterations can result in increased costs and affect the overall safety of the structure. Creating a detailed and accurate design from the onset can mitigate these risks effectively.

Evaluating Material Selection and Its Impact on Structural Efficiency

When designing a steel structure, material selection greatly influences overall efficiency. Steel, known for its strength-to-weight ratio, enables thinner beams and lighter frames. Reports from the American Institute of Steel Construction (AISC) highlight that optimized material choices can reduce up to 30% of total weight in some projects. A lightweight structure often results in lower foundation costs and reduced transportation expenses.

However, not all steel is created equal. Different grades and treatments can lead to varying results. For instance, high-strength steel can offer enhanced performance in seismic regions but can also be more expensive. Sometimes, cost savings compromise safety and longevity. Engineers must evaluate whether a cheaper material genuinely serves the project's requirements.

Tips: Always consider the environmental impact of your choices. Recyclable materials can contribute to sustainable construction goals. Engage with experienced professionals who can guide material selection. Test prototypes before committing to large-scale production; this way, you can identify design flaws early on. Use software to model and simulate how materials behave under different loads. This proactive approach fosters better outcomes and rational decisions.

Implementing Advanced Design Software for Optimal Steel Framework Layout

In the realm of steel structure design, advanced design software is revolutionizing workflows. These tools enable engineers to visualize complex frameworks in 3D. Accurate modeling reduces errors and optimizes material usage. Precision is key, yet human oversight remains vital. A minor mistake in the design phase can lead to significant issues during construction.

Implementing these software systems is not without challenges. Training staff to fully utilize advanced features takes time. Often, teams encounter a steep learning curve. Some may struggle with the intricacies of software updates and new functionalities. Additionally, not all features may fit every project. It's crucial to evaluate which tools align with specific goals.

Architects have reported both successes and setbacks. While new software can streamline collaboration, communication can sometimes falter. Misinterpretations of designs between teams often arise. Embracing feedback is essential in these scenarios. Continuous improvement hinges on reflection and adaptation. Balancing technology with a human touch is the path forward in efficient steel structure design.

Analyzing Load-Bearing Requirements and Structural Integrity Regulations

When designing and building a steel structure, it’s crucial to analyze load-bearing requirements. Understanding how loads impact your design can prevent future problems. Each beam and column must be carefully calculated to bear the intended loads, including live loads, dead loads, and environmental factors. Failing to account for these can lead to structural failure.

Tip: Always consult local regulations. They provide guidelines on minimum load requirements. These codes vary by region and are essential for safety and compliance. Ignoring them may lead to costly rework or unsafe structures.

Another important aspect is structural integrity. Regular inspections and maintenance are key. Corrosion can weaken the steel over time. It’s vital to plan for protective coatings. Without them, the lifespan of the structure may be severely compromised.

Tip: Document all maintenance activities. This helps track the condition over time. It also assists in identifying patterns that may indicate larger issues.

Balancing efficiency and safety can be challenging. New technologies might promise faster construction, but they require careful evaluation. Ensure that any innovative approach does not bypass necessary safety checks. Keep reflecting on your methods to improve future designs.

2026 Load-Bearing Requirements in Steel Structures

This chart showcases the average load-bearing capacity of various steel structural designs, evaluated against industry standards for 2026. It highlights crucial factors such as live load, dead load, and safety factors, providing insights into efficient design practices.

Sustainable Practices in Steel Construction: Cost and Environmental Benefits

Steel construction is gaining popularity due to its efficiency and sustainability. This approach reduces waste and minimizes energy use. Using recycled steel can further lower environmental impact. However, sourcing locally is a challenge. Supply chain issues may arise, increasing costs and delay.

Water usage in steel production is significant. Efforts must be made to manage this effectively. Implementing water recycling systems could be a solution. Yet, not all projects prioritize this aspect, leading to a missed opportunity for sustainability.

Design plays a crucial role in efficiency. Integrating smart technologies can enhance performance. However, some designs overlook the simplicity of structure, complicating the build process. Collaboration among engineers, architects, and builders is vital to ensure that sustainability is at the forefront.

Related Posts

-

Top 10 Benefits of Steel Structure Buildings for Your Construction Projects

-

Top 10 Structural Contractors You Should Know for Your Next Project

-

2025 How to Choose the Right Building Contractor for Your Project

-

Top 10 Benefits of Manufactured Buildings You Need to Know

-

Top 5 Benefits of Pre Engineered Steel Buildings You Need to Know for Your Next Project

-

Understanding the Role of a Building Contractor in Modern Construction Projects