How to Choose the Best Pre Fab Building for Your Next Project

As the construction industry continues to evolve, the popularity of pre fab buildings has surged, driven by their versatility, cost-effectiveness, and reduced construction timelines. According to a report by MarketsandMarkets, the global prefabricated buildings market is expected to reach USD 1 trillion by 2025, growing at a CAGR of 6.5% from 2020. This rapid expansion reflects a growing recognition of pre fab buildings as a sustainable alternative to traditional construction methods. With environmental considerations becoming paramount, the use of pre-fabricated structures can lead to a significant decrease in waste and resource consumption, aligning with the industry's push towards greener building practices.

When embarking on your next project, understanding how to select the best pre fab building option is crucial. Factors such as project scope, budget constraints, and intended use must be meticulously assessed to ensure a successful outcome. Reports from the Modular Building Institute indicate that modular construction can reduce building time by 30% to 50%, further emphasizing the importance of careful planning in leveraging these innovative structures. As the market matures, decision-makers are faced with a myriad of design options and technology advancements, making it essential to stay informed on the latest developments in pre fab building to make educated, strategic choices for future projects.

Understanding Prefabricated Buildings and Their Benefits

Prefabricated buildings, or "prefab" structures, are gaining momentum in the construction industry due to their efficiency and sustainability. According to a report by McKinsey & Company, modular construction can lead to a time savings of up to 50% compared to traditional building methods. This is primarily because prefab structures are built off-site in controlled environments, which minimizes delays caused by weather and on-site disruptions. Additionally, the precision of factory production enhances quality control, helping to reduce waste by approximately 30%, according to the National Institute of Standards and Technology (NIST).

The benefits of prefabricated buildings extend beyond time and waste reduction; they also offer significant cost savings. A study published by the Harvard Business Review indicates that using prefabricated elements can reduce labor costs by as much as 20%. Moreover, prefabricated buildings can provide greater energy efficiency, as they are often designed with modern insulation materials and construction techniques. This results in buildings that are not only quicker to erect but also more environmentally friendly, reflecting a growing trend towards sustainability in the construction sector. As the demand for faster and greener building solutions increases, understanding these benefits is crucial for anyone looking to embark on a construction project.

Assessing Project Requirements and Objectives

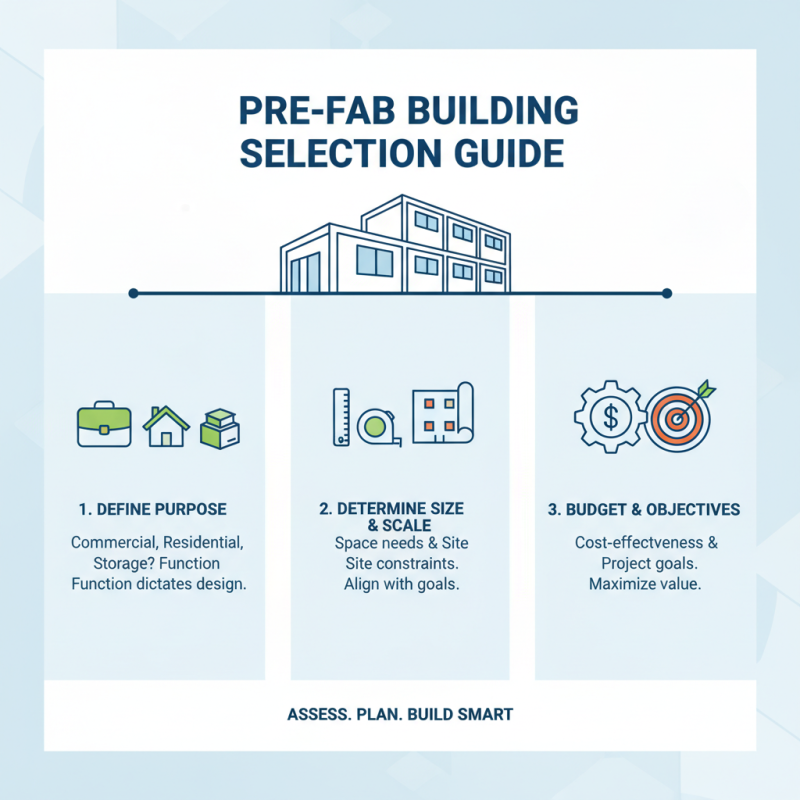

When selecting the best pre-fabricated building for your next project, it is crucial to thoroughly assess your project requirements and objectives. Start by considering the purpose of the building. Is it for commercial use, residential space, or perhaps a storage facility? Understanding the specific function will guide your design choices, construction materials, and layout. Additionally, contemplate the size and scale of your project. How much space do you need, and what are the constraints of your site? These factors should align with your overall goals and budget.

Tips: Make a checklist of must-have features versus nice-to-have additions. This exercise will help you prioritize and remain focused during the selection process. Furthermore, engage stakeholders early on to gather insights and expectations that could shape your decisions.

Another essential aspect to consider is the timeline for your project. Prefabricated buildings often promise faster construction times, but delays in design approval or site preparation can affect your schedule. Establish a clear timeline that includes milestones for design, fabrication, and installation. This will help you maintain momentum throughout the project, ensuring that your objectives are met within the desired timeframe.

Tips: Use project management tools to track progress and maintain communication with your team. Staying organized will help you identify any potential delays early and adjust your plans accordingly.

Evaluating Material Options and Building Designs

When it comes to selecting the best pre-fab building for your next project, evaluating material options and building designs is crucial. The choice of materials not only impacts the durability and longevity of the structure but also affects the overall aesthetic and functionality. Common materials for pre-fab buildings include steel, wood, and concrete. Steel offers strength and resistance to pests and rot, while wood provides natural insulation and a warm aesthetic. Concrete is often appreciated for its durability and fire resistance. Assessing the environmental impact of these materials can also guide your decision, especially if sustainability is a priority for your project.

In addition to materials, the building design plays a significant role in ensuring that the structure meets your specific needs. Factors such as layout, space utilization, and adaptability should be considered. Are you looking for a clear span for open space or specific room divisions? Modular designs allow for flexibility and future expansion, which can be particularly beneficial for projects that may evolve over time. It’s important to consult design principles that optimize energy efficiency and natural lighting, ensuring that your pre-fab building is not only functional but also comfortable and inviting. Making informed choices about materials and design will ultimately lead to a successful project outcome.

Comparing Cost-Effectiveness and Budget Constraints

When selecting a pre-fabricated building for your next project, cost-effectiveness and budget constraints play pivotal roles in the decision-making process. First, it's essential to assess the overall expenses associated with pre-fab structures, which often include materials, transport, assembly, and potential site preparation costs. Conducting a detailed cost analysis can help you evaluate how these expenses compare to traditional construction methods. By doing so, you can identify which pre-fab options offer the best value for your investment while fulfilling the specific needs of your project.

Another factor to consider is the flexibility of your budget. Pre-fabricated buildings can range significantly in price based on size, complexity, and design options. Establishing a clear budget upfront will enable you to narrow down your choices effectively. Additionally, exploring financing options and incentives for sustainable building practices can further enhance the cost-effectiveness of your project. By taking all these factors into account, you can ensure that your decision aligns with your financial goals while meeting project requirements.

Cost-Effectiveness of Pre-Fab Buildings Compared to Traditional Construction

This bar chart compares the average cost per square foot of pre-fabricated buildings to traditional construction methods. As indicated, pre-fab buildings are generally more cost-effective, making them a favorable option for budget-conscious projects.

Selecting a Reliable Manufacturer and Contractor

When selecting a prefabricated building for your next project, one of the most crucial aspects is choosing a reliable manufacturer and contractor. A dependable manufacturer should have a proven track record in the industry, showcasing their ability to produce high-quality prefabricated structures that meet specific regulatory standards. Researching their portfolio, customer reviews, and certifications can provide insight into their credibility. Look for manufacturers who prioritize sustainability and use durable materials, as these factors contribute to the longevity and efficiency of the building.

Once you’ve identified potential manufacturers, it’s essential to collaborate with a contractor who understands the intricacies of prefabricated construction. A skilled contractor will not only manage the installation process but can also provide valuable advice on design changes and compliance with local building codes. Communicating your project requirements effectively and ensuring that the contractor has experience with prefab buildings can lead to a smoother construction process. Ultimately, thorough due diligence in selecting both a manufacturer and contractor will help ensure that your prefabricated building project is a success.

Related Posts

-

Why Pre Fab Building is the Future of Sustainable Construction

-

Top 10 Structural Contractors You Should Know for Your Next Project

-

2025 Top 10 Innovative Construction Materials Revolutionizing Building Industry

-

Mastering Safety Protocols: Essential Strategies for a Successful Construction Site

-

How to Create Innovative Building Design for Modern Architecture

-

Understanding the Role of Residential Contractors in Home Renovation Projects